VDL PVC Equal Tees

VDL are a leading manufacturer of PVC fittings. The Tees are made from U- PVC and are 16 bar rated. The are a precision made product made in a state of the art manufacturing plant in the Netherlands.

| 2.01.016* | 16 | 9 | 14 | 16 | 200 (4 x 50) | |

| 2.01.020* | 20 | 11 | 16 | 16 | 100 (2 x 50) | |

| 2.01.025* | 25 | 13.5 | 19 | 16 | 250 | |

| 2.01.032* | 32 | 17 | 22 | 16 | 225 | |

| 2.01.033 | 32 | 17 | 22 | 10 | 250 | |

| 2.01.040* | 40 | 23 | 26 | 16 | 125 | |

| 2.01.050* | 50 | 27 | 32 | 16 | 75 | |

| 2.01.063* | 63 | 32.5 | 38 | 16 | 38 | |

| 2.01.075 | 75 | 40 | 44 | 10 | 24 | |

| 2.01.076 | 75 | 38.5 | 44 | 10 | 24 | |

| 2.01.090 | 90 | 48 | 51 | 16 | 14 | |

| 2.01.110 | 110 | 63 | 61 | 16 | 7 | |

| 2.01.125 | 125 | 66.5 | 69 | 16 | 4 | |

| 2.01.140 | 140 | 73.5 | 76 | 16 | 2 | |

| 2.01.160 | 160 | 83 | 86 | 16 | 2 |

PVC-U

PVC-U is a Polyvinylchloride without plasticizers that is extremely suitable for very wide applications, such as:

- Chemical installations

- Portable water applications

- Food and beverage industry

- Sanitary and swimming pool technology

- Irrigation

The main advantages of PVC-U are:

- Excellent chemical resistance

- Corrosion resistance

- Easy installation

- Durability

- Low maintenance

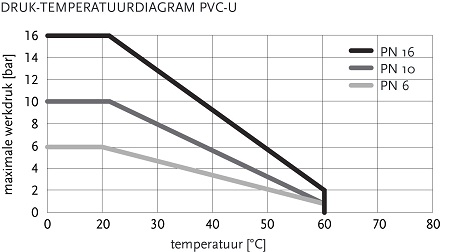

Pressure and temperature diagram

PVC-U has very good properties in a temperature range of 0°C to 60°C. At lower temperatures the impact resistance clearly decreases.

Figure 1

Figure 1 shows the maximum operating pressure for PN16, PN10 and PN6 fittings. This information is based on a lifespan of 50 years with a safety factor of 2.5.

Chemical Resistance

The chemical resistance of PVC-U depends on the conditions of use and must be assessed for each situation.

For more information, see the chemical resistance list.

Dimensions and standards PVC-U

The fittings correspond to the following standards:

- DIN 8063

- ISO 727

- KIWA nr. BRL-K 504